1. Einleitung

The xTool P2 is a versatile and intelligent desktop CO2 laser cutter and engraver, designed for both hobbyists and small businesses. Equipped with a powerful 55W laser tube and dual 16MP smart cameras, it offers exceptional precision for a wide range of materials and applications. Its advanced features include automatic 3D model construction for curved surface engraving, intelligent shape recognition for batch processing, and automatic passthrough for extra-long materials.

This manual provides essential information for setting up, operating, maintaining, and troubleshooting your xTool P2 to ensure safe and efficient use.

Figure 1: The xTool P2 55W CO2 Laser Cutter.

Abbildung 2: Überview of xTool P2's key features and capabilities.

Produkt überview Video

Video 1: Ein überview of the xTool P2, showcasing its versatility in various creative projects and applications.

2. Einrichtung

Before operating your xTool P2, ensure proper setup by following these steps:

- Auspacken und Platzierung: Carefully remove the machine from its packaging. Place the xTool P2 on a stable, level surface in a well-ventilated area, away from flammable materials.

- Schutzmaterialien entfernen: Open the lid and remove all internal foam packaging and protective films from the machine's components.

- Install Slats/Honeycomb Panel: Place the provided slats or honeycomb panel into the working area.

- Fill Coolant Reservoir: Locate the coolant reservoir (typically at the back or side of the machine). Unscrew the cap and carefully pour distilled water or recommended antifreeze (if ambient temperature is below 10°C/50℉) into the reservoir until it reaches the indicated fill line. Securely replace the cap.

- Strom und USB anschließen: Plug the power cable into the machine and a grounded electrical outlet. Connect the USB cable from the xTool P2 to your computer.

- Softwareinstallation: Download and install the xTool Creative Space (XCS) software from the official xTool webFolgen Sie den Anweisungen auf dem Bildschirm zur Installation.

- Erstes Einschalten: Press the power button on the machine. The indicator lights should illuminate, and the laser head will perform an initialization sequence.

3. Bedienungsanleitung

The xTool P2 offers intuitive operation for both cutting and engraving tasks. Familiarize yourself with its core functionalities:

3.1 Grundlegender Arbeitsablauf

- Material vorbereiten: Place your chosen material (e.g., wood, acrylic, leather) onto the working bed. Ensure it lies flat and is secured if necessary.

- Software Setup (XCS): Open the XCS software. The dual HD cameras will provide a real-time preview of your material on the canvas.

- Import/Create Design: Importieren Sie Ihr Design file (SVG, DXF, PNG, JPG, etc.) or create a new design directly within XCS.

- Position and Adjust: Drag and resize your design on the canvas to align it with your material. Utilize the precise positioning features of the dual cameras for accurate placement, especially for small objects.

- Parameter einstellen: Select the material type from the software's library or manually set the laser power, speed, and pass count based on your material and desired effect (cutting, engraving, scoring).

- Verarbeitung starten: Once all settings are configured, click the "Process" button in the software. The machine will begin its operation. Monitor the process through the transparent lid.

Figure 3: The powerful 55W CO2 laser cutting thick materials in a single pass.

3.2 Erweiterte Funktionen

- Curved Surface Engraving: The xTool P2 can automatically construct 3D models of curved objects using its smart cameras, allowing for precise engraving on non-flat surfaces. This feature ensures consistent results across varying contours.

Figure 4: Engraving intricate designs on curved surfaces with ease.

Curved Surface Engraving Video

Video 2: Demonstration of the xTool P2's curved surface engraving capabilities.

- Automatic Passthrough: For extra-long materials, the xTool P2 supports an automatic conveyor feeder (sold separately) that allows continuous processing of materials up to 118 inches long. This is ideal for large-scale projects like signage.

Figure 5: The automatic passthrough feature for processing extended materials.

Automatic Conveying Video

Video 3: Showcasing the automatic conveying feature for continuous material processing.

- Zwei HD-Kameras: The integrated 16MP cameras provide a panoramic view for overall design preview and a close-range view for ultra-fine detail positioning, ensuring accurate placement and minimizing material waste.

Figure 6: The dual HD camera system for precise object positioning.

- DistiMaster™ Ranging System: This advanced LiDAR technology ensures precise auto-focus, delivering accurate distance measurements and consistent cut-through results every time.

Figure 7: The DistiMaster™ Ranging System for accurate auto-focus.

3.3 Materialverträglichkeit

The xTool P2 is compatible with a wide array of materials, including but not limited to:

- Wood (various types, including black walnut, basswood, MDF)

- Acrylic (all colors)

- Leder

- Gummi

- Stoff

- Glass (engraving only)

- Ceramic (engraving only)

- Slate (engraving only)

- Coated Metal (engraving only)

- Anodized Aluminum (engraving only)

3.4 Business Applications

The xTool P2 is an excellent tool for various business ventures, enabling the creation of custom products and signage.

Abbildung 8: Bspample of an Event Planner utilizing the xTool P2.

Abbildung 9: Bspample of a Sign Maker utilizing the xTool P2.

Abbildung 10: Bspample of a Jewelry Designer utilizing the xTool P2.

Abbildung 11: Bspample of a Woodworker utilizing the xTool P2.

Easy Start Your Small Business Video

Video 4: Showcasing how the xTool P2 can help easily start a small business.

4. Wartung

Regular maintenance ensures the longevity and optimal performance of your xTool P2.

- Linsen- und Spiegelreinigung: Regularly inspect and clean the laser lens and mirrors using a lint-free cloth and lens cleaning solution. Refer to the detailed instructions in the official user manual for proper cleaning procedures.

- Honeycomb Panel Cleaning: The honeycomb panel can accumulate residue from cutting. Periodically remove and clean it to maintain efficient smoke exhaust and prevent material staining.

- Kühlmittelstand prüfen: Monitor the coolant level in the reservoir. Refill with distilled water or appropriate antifreeze as needed, especially if operating in temperatures below 10°C (50℉).

- Exhaust Fan Maintenance: Ensure the exhaust fan is clear of debris to maintain proper ventilation and smoke extraction.

5. Fehlerbehebung

If you encounter issues with your xTool P2, consider the following common troubleshooting steps:

- Maschine lässt sich nicht einschalten: Check the power cable connection to both the machine and the electrical outlet. Ensure the emergency stop button is not engaged.

- Laser Not Firing/Cutting: Verify that the lid is fully closed and latched. Check laser power and speed settings in the software; they might be too low for the material. Ensure the material is within the focal range.

- Poor Cut/Engrave Quality: This can be due to incorrect material settings, a dirty lens or mirrors, or improper focus. Clean optical components and recalibrate focus if necessary.

- Softwareverbindungsprobleme: Ensure the USB cable is securely connected. Restart both the machine and the software. Try a different USB port or cable.

- Warnung vor Überhitzung: Check the coolant level. Ensure the exhaust fan is working and not obstructed. Allow the machine to cool down before resuming operation.

For persistent issues, refer to the comprehensive troubleshooting guide in the official user manual or contact xTool customer support.

6. Spezifikationen

| Besonderheit | Detail |

|---|---|

| Modell | xTool P2 (MXP-K002-004) |

| Laserleistung | 55W (55000mW) CO2 Laser |

| Gravurgeschwindigkeit | Bis zu 600 mm/s |

| Bettgröße | 26" x 14" (660 mm x 355 mm) |

| Max. Engraving Height | 2.7" (68mm) (8.4" with Riser Base) |

| Kameras | Dual 16MP Smart Cameras (Panoramic & Close-range) |

| Autofokus | DistiMaster™ Ranging System (LiDAR) |

| Konnektivität | USB, WLAN |

| Technische Daten | 25 x 11 x 39.5 Zoll |

| Artikelgewicht | 126.4 Pfund |

| Sicherheitsfunktionen | Enclosed design, Automatic lock, Emergency stop button, Hydraulic support, Fire safety, Multiple warning systems |

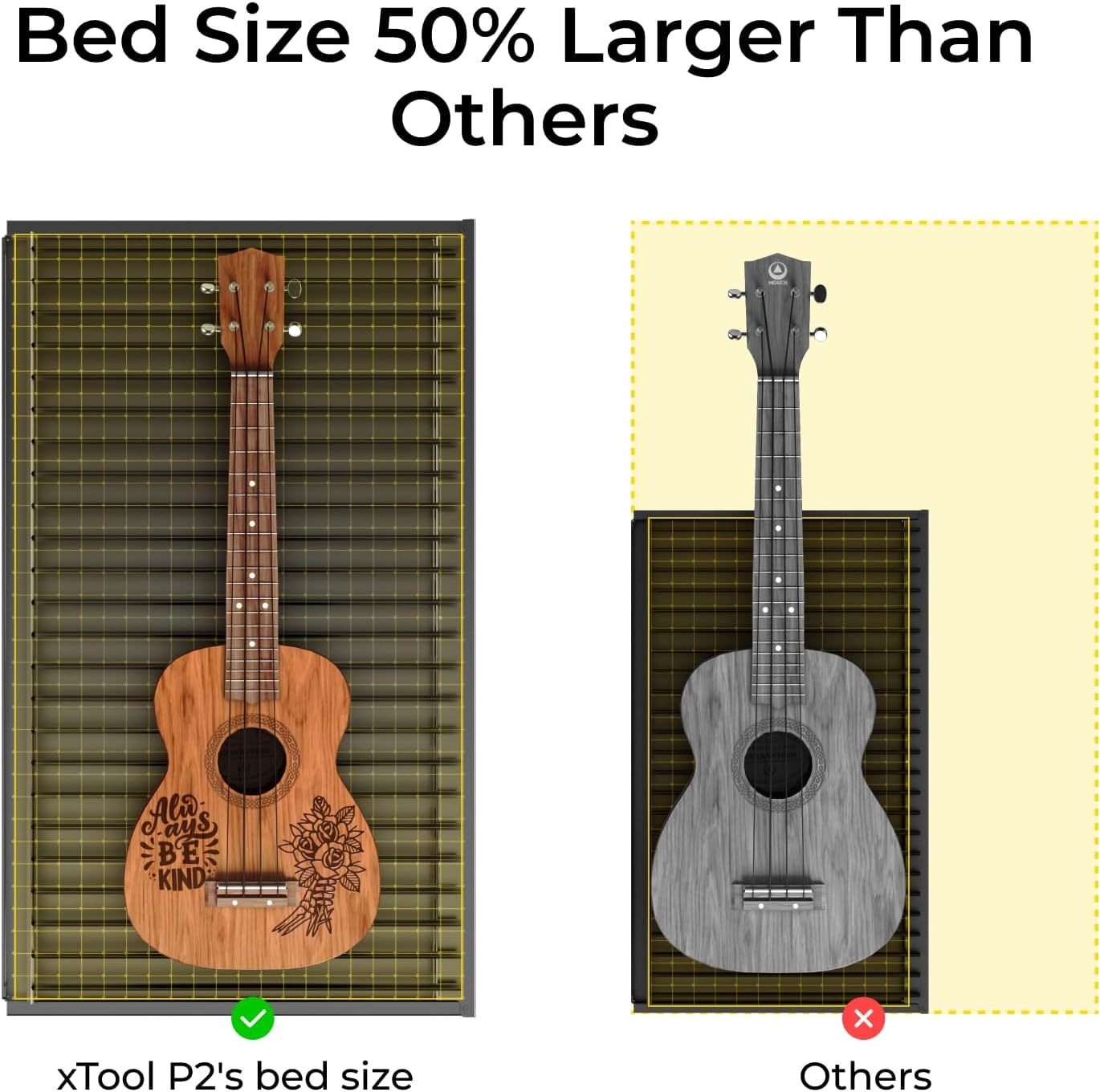

Figure 12: Comparison of xTool P2's bed size with other models.

Figure 13: Detailed feature comparison of xTool P2 against competitors.

7. Garantie und Support

xTool provides comprehensive support for its products:

- Garantie: The xTool P2 comes with a 1-year warranty. Please retain your proof of purchase for warranty claims.

- Kundendienst: For technical assistance, troubleshooting, or any inquiries, you can reach xTool customer support through multiple channels:

- E-Mail-Support

- Live chat on the official webWebsite

- Telefon-Support

- Facebook group for community support and discussions

Figure 14: xTool's multi-channel service options for customer support.

Figure 15: The dedicated xTool technical service team.